QKL-B1T/QKL-B3-AI

Low Pressure Proportional Regulator (0-8bar)

SHARE

Low Pressure Proportional Regulator (0-8bar)

There are 3 different series of 0-8 bar proportional pressure regulator- low flow < 20L/min, high flow > 500 L/min, and economic type high flow. The low flow version consists of two solenoid valves, one high-processing speed digital electronic board, and one pressure transducer. The high flow version's construct is similar, but adding a volume booster. The economic type of proportional pressure regulator is the one where we offer a reasonable accuracy 0.5%, high speed, and economics type for customers requiring simple operations.

Features and Applications

QKL-B1T low flow electro pneumatic pressure regulator have selections of three output pressure range- 2 bar, 4 bar, 8 bar. With the 2 bar version, it is possible to customize the pressure range to lower value. This features ultra-high resolution of 0.0005 bar, ultra-high stability and quick response time. This electro pneumatic pressure regulator has been widely used in the microfluidics industry in world-leading US medical device manufacturer, and it is also popular amongst dispensing and dosing industry.

QKL-B3 is the high flow version of 8 bar electronic pressure regulator valve. Having an extra volume booster provides a higher flow to the application and allows dynamic working conditions. It offers a high accuracy of 0.1 – 0.25%, high repeatability, and flow rate of 1200 L/min. Many have used QKL-B3 to control pressure in a large closed tank applications encompass semi-conductor testing equipment, dry-process equipment, and manufacturing equipment.

QKL-B3-A is the economic high flow version of electronic pressure regulator valve where the customers have simple applications of pressure regulation. It features quick pressure switch time, high flow, and economic. There is a major application of this electro pneumatic pressure regulator in low pressure gas control in laser cutting machine.

Working Principle

An electronically controlled pressure regulator consist of one high speed processing electronic board, one air pressure transducer, one normally closed solenoid valve to allow air inlet, and one normally closed solenoid valve to allow air exhaust. When the electronics receive electronic signal (0-10V, 4-20mA or digital) from the controller, it will command the solenoid valve to open to allow air inlet into the electronic pressure regulator. The in-built air pressure transducer received senses the pressure and converts it to digital signal. The electronic will compare the set signal with the output pressure. If one is higher than the other, it will command either inlet valve or exhaust valve to operate. This PID loop of working principle will stop until the set signal equals to the output pressure. This way the electronically controlled pressure regulator can accurate change the output pressure according to customers set command signal.

Advantage / Benefits

Because of the high resolution characteristic of low pressure electronically controlled pressure regulator, it has been used in couple with.

1. Air pressure ratio regulator

With the air pressure ratio regulator, the output pressure from the electronically controlled pressure regulator is amplified in ratio with the dome pressure regulator. It is normally 20 times ratio. Because of the amplification, the resolution and stability of the electronic pressure regulator is critical in this chimera. The 2 bar and the 8 bar version has been widely used with different air ratio regulators providing a stable high pressure control regulator up to 210 bar (3000 psig).

2. Volume booster

Low pressure electronically controlled pressure regulator often has low flow rate, limiting the application scenarios. Pairing the regulator with a volume booster (1/2" ~ 2") high precision volume booster allows accurate control of ultra-high flow rate whilst maintaining fine control in air pressure. It has been used in many blow molding or blowing process applications.

3. Steam pressure / water pressure dome pressure regulator

Electronic control of steam pressure and water pressure is critical in many processing industries, such as food manufacturing or tire manufacturing

4. Back Pressure Regulator

Back pressure regulator can be piloted by electronically controlled pressure regulator to regulate either back pressure or forward flow rate. Our regulator features quick response time and stable set value pressure. Please refer to our website on back pressure regulator.

| Dome Loaded Regulator Types | Low Pressure Proportional Pressure Regulator | Comments |

|---|---|---|

| Air Pressure Ratio Regulator | 2 bar – 10 bar selections | 1: 20 ratio |

| Volume Booster | 0 – 8 bar, selections | From 1/2" to 2" port, 4200 L/min at 3 bar. |

| Steam Pressure | 0 – 8 bar, higher pressure is also available. | Stainless steel material available. Up to 220°C |

| Water Pressure | 0 – 8 bar, high pressure is also available. | Fluid type can be pure water to slurry |

| Back Pressure Regulator | Requiring higher performance regulator, consult for customization. | Used for back pressure control or flow rate control |

Table 1. Using electro pneumatic pressure regulator with different types of dome loaded regulator

FAQ

1. If I intend to output 0.1 psi of air, what is the maximum inlet air pressure to the regulator ?

A. It is recommended to set inlet air pressure regulator as close to the output air pressure for high resolution control.

2. Can I achieve a resolution control such as 0.3 psi change with volume booster?

A. It is not possible.

3. I need a low flow rate 4 bar electronic pressure regulator, but there is a slight flow rate from the container, would QKL-B1T be suitable?

A. Please provide the flow rate, if it is below 4 L/min, it would be possible. Please remember to inform our application engineer for this special request.

Features

- Small Size

- High Precision

- High Sensitivity

- Wide Pressure Range

Industrial application

- Laser Cutter

- Leak Tester

- Tension Control

- PET bottle molding machine

- Multi-Stage Pressure Control

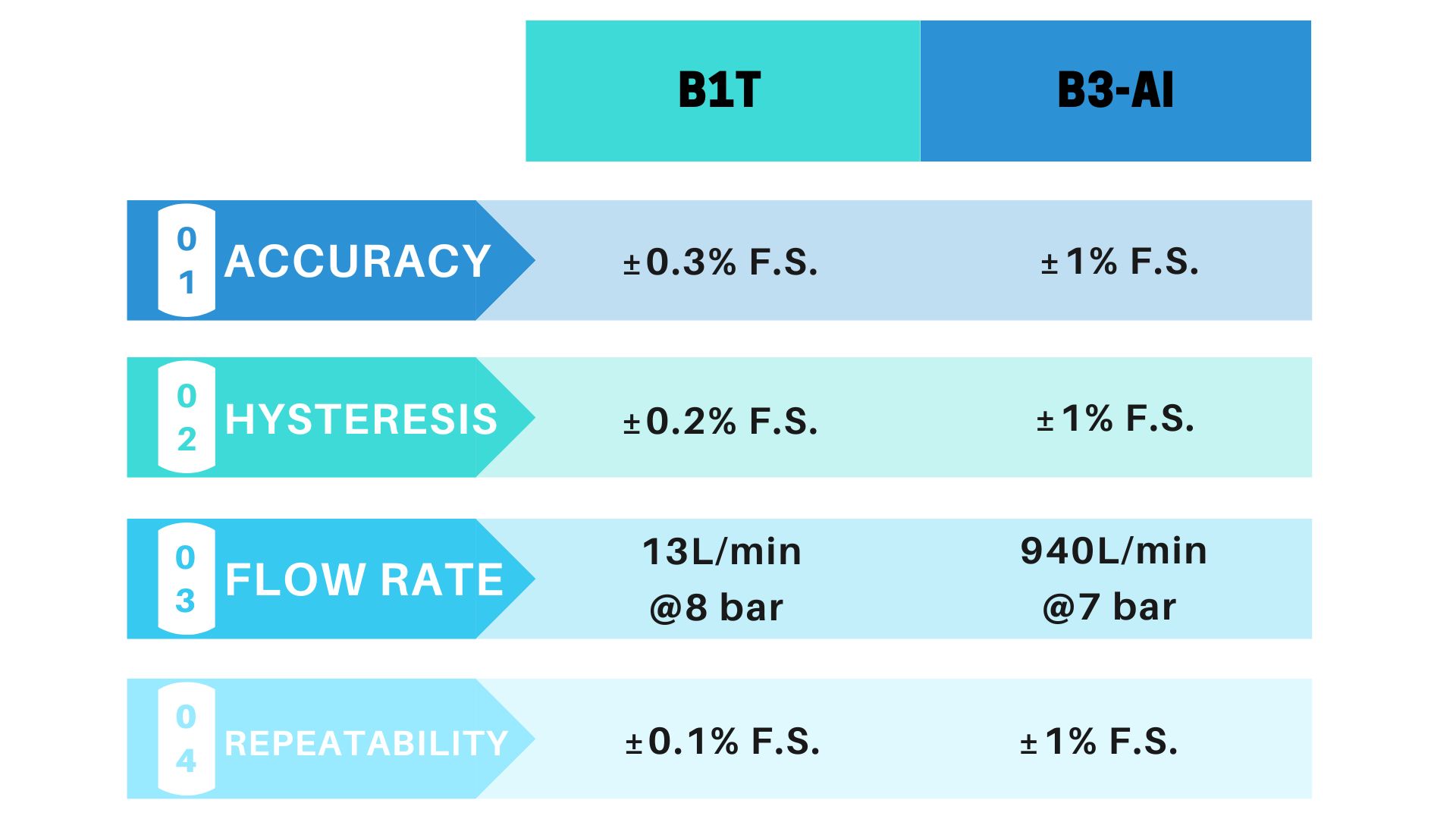

| Type | B1T | B3-AI (economic type) | ||

|---|---|---|---|---|

| Input Signal | 0-10V / 4-20mA / RS485 | |||

| Output Range | 0-2bar (29psi) |

0-4bar (58psi) |

0-8bar (116psi) |

0-7bar (102psi) |

| *Suggesting Supply Pressure Max | 3bar (43psi) |

5bar (73psi) |

9bar (131psi) |

8bar (116psi) |

| Monitor Output | 1-5V / 0-10V / 4-20mA / RS485 | |||

| Power Supply | DC24V (≦4W) | |||

| Response | 0.8S | |||

| Medium | Clean compressed air or with 5 µm filter | |||

| Repeatability | ±0.1% F.S. | ±1% F.S. | ||

| Hysteresis | ±0.2% F.S. | ±1% F.S. | ||

| Linearity | ±0.3% F.S. | ±1% F.S. | ||

| Accuracy | ±0.3% F.S. | ±1% F.S. | ||

| Flow Rate | 4L/min @2bar |

7L/min @4bar |

13L/min @8bar |

940L/min @7bar |

| Temp. Range(Operating) | 0-70 ⁰C ( 32-158 ⁰F) | |||

| Port Size | PT 1/8" | G1/4" | ||

| Manifold Material | Aluminum | |||

| Wetted Materials | Aluminum, Stainless steel, NBR | |||

| Mounting Bracket Material | Galvanized Steel | |||

| Electrical Connection | M12 Connector (2m) | |||

| Ingress Protection | IP 65 | |||

| Life Cycle | Over 1 Billion Times | |||

| Weight | 420 g | 440 g | ||

*If the supply pressure would higher than we suggested, please contact with our sales for the the most suitable operation.