Y型蒸氣閥(全白鐵)

分享

| 管道壓力 | Max 16 bar |

|---|---|

| 控制壓力 | 3~8 bar |

| 控制介質 | 中性氣體或空氣 |

| 氣缸尺寸 | 40mm, 50mm, 63mm, 90mm, 125mm |

| 適用介質 | 水、酒精、油、燃料、蒸氣、中性氣體或液體、有機溶劑、酸鹼溶液 |

| 介質黏度 | Max 600mm ²/s |

| 介質溫度 | -10℃~180℃, 25℃~220℃ |

| 環境溫度 | -10℃~80℃ |

| 控制形式 | 單動-常閉、單動-常開、雙動 |

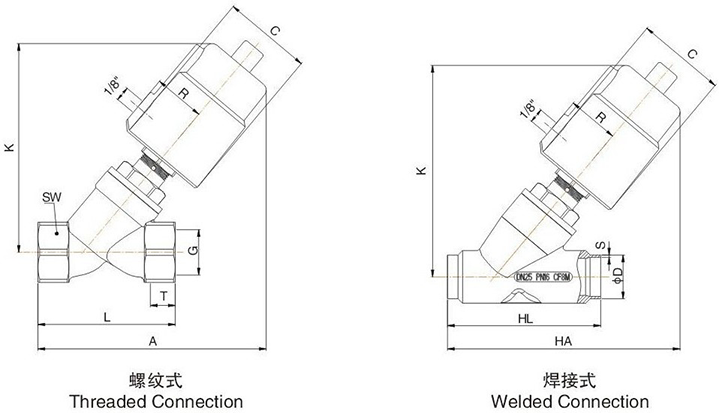

| 連接形式 | 螺紋式、焊接式、法蘭式、快裝式 |

| 規格 | 執行器 (mm) | C | R | K | 螺紋式 | 焊接式 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G | T | A | L | SW | HA | HL | DIN11850-2 | DIN11850-3 | SMS3008 | ||||||||||

| D | S | D | S | HA | HL | D | S | ||||||||||||

| DN10 | 40 | 50.5 | 27 | 211 | 3/8" | 12 | 119 | 68 | 27 | - | - | - | - | - | - | - | - | - | - |

| 50 | 60 | 33 | 124 | 131 | - | - | - | - | - | - | - | - | - | - | |||||

| DN15 | 40 | 50.5 | 27 | 111 | 1/2" | 15 | 119 | 68 | 27 | 118 | 70 | 19 | 1.5 | 20 | 2 | 127 | 75 | 18 | 1 |

| 50 | 60 | 33 | 124 | 131 | 128 | 138 | |||||||||||||

| DN20 | 50 | 60 | 33 | 128 | 3/4" | 16 | 136 | 75 | 32 | 135 | 82 | 23 | 1.5 | 24 | 2 | 145 | 95 | 25 | 1.2 |

| DN25 | 50 | 60 | 33 | 136 | 1" | 17 | 145 | 90 | 40 | 150 | 100 | 29 | 1.5 | 30 | 2 | 165 | 130 | 32 | 1.2 |

| 63 | 75 | 41 | 162 | 169 | 175 | 188 | |||||||||||||

| 90AL | 112 | 57 | 210 | 211 | 216 | 230 | |||||||||||||

| 90 | 106 | 55 | 211 | 213 | 218 | 232 | |||||||||||||

| DN32 | 63 | 75 | 41 | 174 | 1"1/4 | 21 | 187 | 116 | 50 | 186 | 125 | 35 | 1.5 | 36 | 2 | 200 | 145 | 33.7 | 1.2 |

| 90AL | 112 | 57 | 220 | 229 | 230 | 242 | |||||||||||||

| 90 | 106 | 55 | 223 | 231 | 232 | 245 | |||||||||||||

| DN40 | 63 | 75 | 41 | 175 | 1"1/2 | 21 | 187 | 116 | 56 | 190 | 130 | 41 | 1.5 | 42 | 2 | 210 | 160 | 38 | 1.2 |

| 90AL | 112 | 57 | 220 | 230 | 232 | 252 | |||||||||||||

| 90 | 106 | 55 | 223 | 231 | 235 | 255 | |||||||||||||

| DN50 | 63 | 75 | 41 | 183 | 2" | 22 | 201 | 138 | 69 | 206 | 155 | 53 | 1.5 | 54 | 2 | 224 | 175 | 51 | 1.2 |

| 90AL | 112 | 57 | 232 | 244 | 247 | 263 | |||||||||||||

| 90 | 106 | 55 | 232 | 247 | 250 | 265 | |||||||||||||

| DN65 | 90AL | 112 | 57 | 262 | 2"1/2 | 26 | 282 | 178 | 85 | - | - | - | - | - | - | - | - | - | - |

| 90 | 106 | 55 | 265 | 285 | - | - | - | - | - | - | - | - | - | - | |||||

| 125AL | 148 | 74 | 302 | 320 | - | - | - | - | - | - | - | - | - | - | |||||

| DN80 | 125AL | 148 | 74 | 313 | 3" | 27 | 372 | 210 | 100 | - | - | - | - | - | - | - | - | - | - |

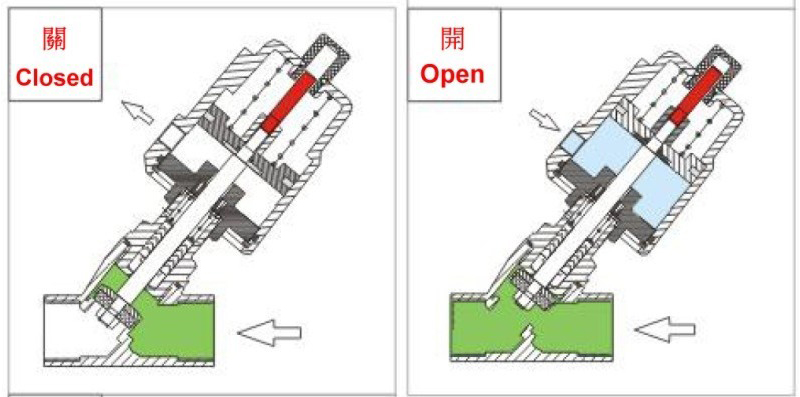

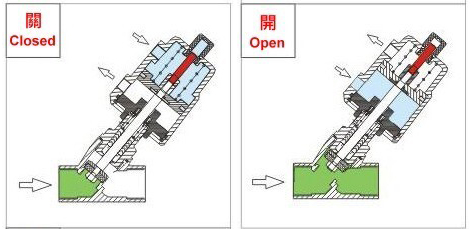

單作用常閉閥-閥座上流

適用於可壓縮性介質,例如氣體,水蒸氣等;以及壓力較低的液體介質

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3 /h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 40 | 0-16 | 3-4.5 |

| 50 | 0-16 | 3-3.5 | ||||

| DN15 | G1/2" | 13 | 4.7 | 40 | 0-16 | 3-4.5 |

| 50 | 0-16 | 3-3.5 | ||||

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-16 | 3-4 |

| DN25 | G1" | 24 | 18.1 | 50 | 0-16 | 3-4.5 |

| 63 | 0-16 | 3-3.5 |

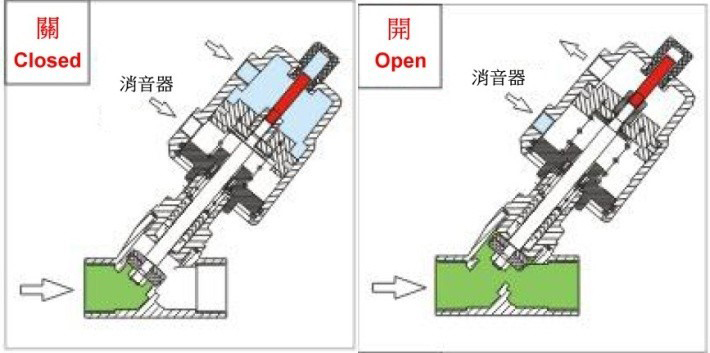

單作用常閉閥-閥座下流(防水錘)

適用於防水錘管道,可承受一定壓差

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3/h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 40 | 0-11 | 3 |

| 50 | 0-14 | 3 | ||||

| DN15 | G1/2" | 13 | 4.7 | 40 | 0-11 | 3 |

| 50 | 0-14 | 3 | ||||

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-14 | 3 |

| DN25 | G1" | 24 | 18.1 | 50 | 0-4 | 3 |

| 63 | 0-14 | 4.5 | ||||

| 90 | 0-16 | 5 | ||||

| DN32 | G1"1/4 | 31 | 23.1 | 63 | 0-6 | 4.5 |

| 90 | 0-16 | 5 | ||||

| DN40 | G1"1/2 | 35 | 32.9 | 63 | 0-5 | 4.5 |

| 90 | 0-16 | 5 | ||||

| DN50 | G2" | 45 | 52.8 | 90 | 0-10 | 5 |

| DN65 | G2"1/2 | 61 | 82.6 | 90 | 0-7 | 5 |

| 125 | 0-9.5 | 6 | ||||

| DN80 | G3" | 80 | 127 | 125 | 0-6 | 6 |

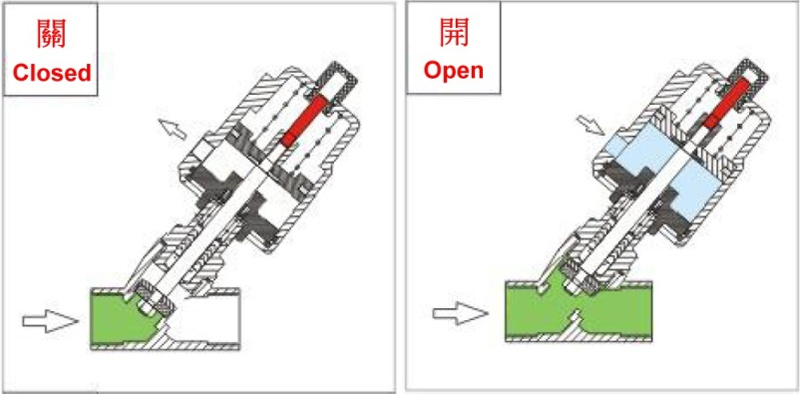

雙作用常閉閥-閥座上流

性能可靠,可承受較大壓差;如遇緊急情況,閥門可自動關閉

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3 /h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 40 | 0-16 | 3-4.5 |

| 50 | 0-16 | 3-3.5 | ||||

| DN15 | G1/2" | 13 | 4.7 | 40 | 0-16 | 3-4.5 |

| 50 | 0-16 | 3-3.5 | ||||

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-16 | 3-4 |

| DN25 | G1" | 24 | 18.1 | 50 | 0-16 | 3-4.5 |

| 63 | 0-16 | 3-3.5 | ||||

| DN32 | G1"1/4 | 31 | 23.1 | 63 | 0-16 | 3-5.5 |

| 90 | 0-16 | 2.5-3.5 | ||||

| DN40 | G1"1/2 | 35 | 32.9 | 63 | 0-16 | 3-6.5 |

| 90 | 0-16 | 2.5-4 | ||||

| DN50 | G2" | 45 | 52.8 | 63 | 0-10 | 3-7 |

| 90 | 0-16 | 2.5-4.5 | ||||

| DN65 | G2"1/2 | 61 | 82.6 | 90 | 0-10 | 2.5-6 |

| 125 | 0-16 | 3-4 | ||||

| DN80 | G3" | 80 | 127 | 125 | 0-16 | 3-7 |

雙作用常閉閥-閥座下流(防水錘)

適用於要求高的防水錘管道,可承受較大壓差

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3 /h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 40 | 0-16 | ≧3 |

| 50 | 0-16 | ≧3 | ||||

| DN15 | G1/2" | 13 | 4.7 | 40 | 0-16 | ≧3 |

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-16 | ≧3 |

| DN25 | G1" | 24 | 18.1 | 50 | 0-13 | 3-5 |

| 63 | 0-16 | 3-4 | ||||

| DN32 | G1 1/4" | 31 | 23.1 | 63 | 0-16 | 3-6 |

| 90 | 0-16 | 2.5-4 | ||||

| DN40 | G1 1/2" | 35 | 32.9 | 63 | 0-16 | 3-7 |

| 90 | 0-16 | 2.5-5 | ||||

| DN50 | G2" | 45 | 52.8 | 63 | 0-8 | 3-7 |

| 90 | 0-16 | 2.5-6 | ||||

| DN65 | G2 1/2" | 61 | 82.6 | 90 | 0-11 | 2.5-7 |

| 125 | 0-16 | 3.5-5 | ||||

| DN80 | G3" | 80 | 127 | 125 | 0-16 | 3-6.5 |

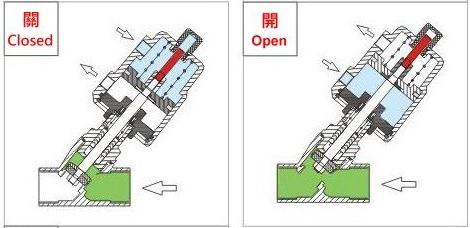

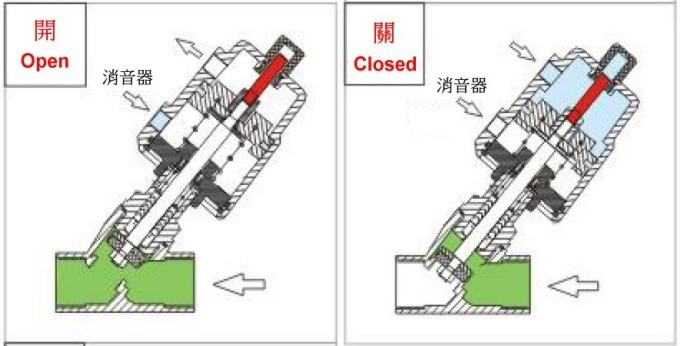

常開閥-閥座上流

適用於要求閥門長時間開啟的管道,取下消音器即為雙作用常開閥

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3 /h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 50 | 0-16 | ≧3 |

| DN15 | G1/2" | 13 | 4.7 | 50 | 0-16 | ≧3 |

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-12 | ≧3 |

| DN25 | G1" | 24 | 18.1 | 63 | 0-16 | ≧4.5 |

| DN32 | G1 1/4" | 31 | 23.1 | 63 | 0-14 | ≧4.5 |

| DN40 | G1 1/2" | 35 | 32.9 | 63 | 0-14 | ≧4.5 |

| DN50 | G2" | 45 | 52.8 | 63 | 0-6 | ≧4.5 |

常開閥-閥座下流(防水錘)

適用於要求閥門長時間開啟的管道,防水錘,取下消音器即為雙作用常開閥

| 規格 | 接口 | 內孔 (mm) |

流量值 (m3 /h) |

執行器 (mm) |

壓差範圍 (bar) |

控制壓力 (bar) |

|---|---|---|---|---|---|---|

| DN10 | G3/8" | 13 | 3.8 | 50 | 0-16 | 2-4 |

| DN15 | G1/2" | 13 | 4.7 | 50 | 0-16 | 2-4 |

| DN20 | G3/4" | 18 | 9.5 | 50 | 0-16 | 2-6 |

| DN25 | G1" | 24 | 18.1 | 50 | 0-13 | 2-6 |

| 63 | 0-16 | 2.5-5 | ||||

| DN32 | G1"1/4 | 31 | 23.1 | 63 | 0-13 | 2.5-6 |

| DN40 | G1"1 | 35 | 32.9 | 63 | 0-7 | 2.5-6 |

| DN50 | G2" | 45 | 52.8 | 63 | 0-5 | 2.5-6 |

| 90 | 0-12 | 2.5-6 | ||||

| DN65 | G2"1/2 | 61 | 82.6 | 125 | 0-14 | 2.5-7 |

| DN80 | G3" | 80 | 127 | 125 | 0-12 | 2.5-7 |

| 型號 | 規格 | 執行器 | 閥體功能 | 牙口 | |||

|---|---|---|---|---|---|---|---|

| 100 | DN-20 | - | 50 | SS | - | - | G3/4 |

| DN-10 | 40 | - : 常閉 | G3/8(DN-10) | ||||

| DN-15 | 50 | NO: 常開 | G1/2(DN-15) | ||||

| DN-20 | 63 | D: 雙動 | G3/4(DN-20) | ||||

| DN-25 | 90 | G1"(DN-25) | |||||

| DN-32 | 125 | G1"1/4(DN-32) | |||||

| DN-40 | G1"1/2(DN-40) | ||||||

| DN-50 | G2"(DN-50) | ||||||

| DN-65 | G2"1/2(DN-65) | ||||||

| DN-80 | G3"(DN-80) |