This series is a complete closed loop servo system consisting of two solenoid valves, an internal pressure

transducer, and electronic controls. Based...

Our electronically controlled pressure regulator is a complete closed-loop servo system consisting of two solenoid valves, an internal pressure transducer, and electronic controls. Based on analog signals, the pressure is controlled by two solenoid valves to maintain precise pressure; one valve functions as inlet control, the other as exhaust. The pressure output is measured by an internal or an external feedback pressure transducer that provides a feedback signal to the electronic controls.

Electronic Pressure Regulator Selection

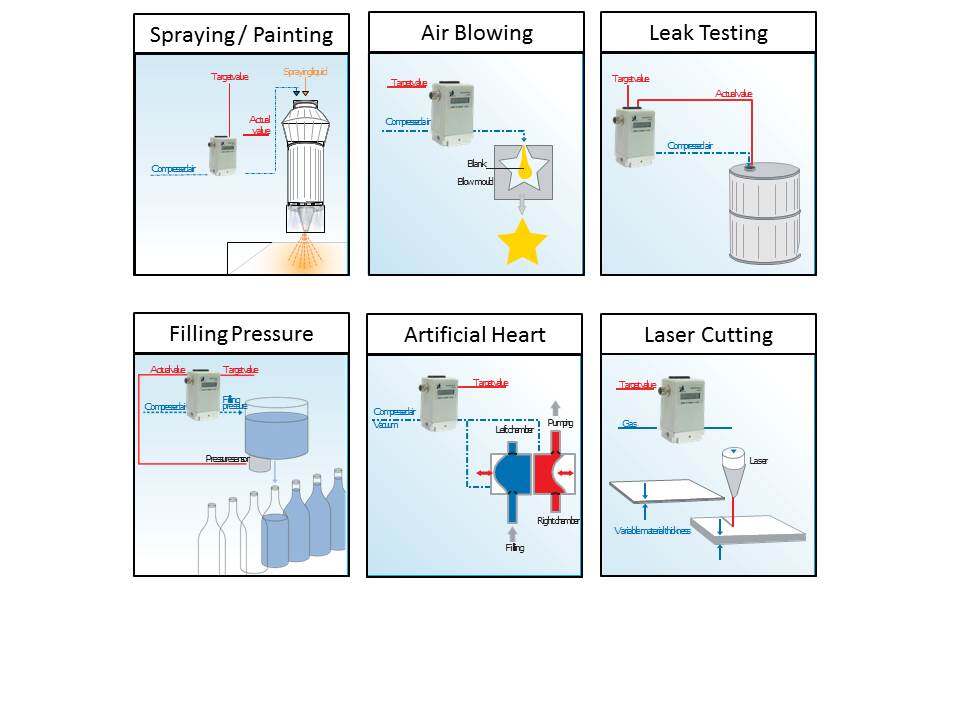

Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pressure regulators and electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc.

They are the same products with different names.

Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines...etc.

No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm.

Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag.

A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control.

Electronic pressure regulators maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications.

Electronic pressure regulators are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static.

Please check our video on: https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ